Mastering High Pressure: A Deep Dive into the Working Principle of Horizontal Multistage Centrifugal Pumps

Unlocking High-Pressure Fluid Transfer: The Definitive Guide to Horizontal Multistage Centrifugal Pumps

In the vast universe of fluid dynamics and industrial processing, achieving high pressure efficiently is a critical challenge. For countless applications, from supplying water to skyscrapers to powering industrial cleaning systems, the horizontal multistage centrifugal pump stands as a testament to engineering excellence. These robust machines are the unsung heroes behind many operations that require significant pressure, offering reliability and performance where single-stage pumps fall short. This comprehensive article delves into the core of how these powerful pumps work, their structural components, and why they are indispensable across so many sectors.

What Exactly is a Horizontal Multistage Pump?

A horizontal multistage pump is a type of centrifugal pump that features two or more impellers mounted on a single, horizontally oriented shaft. The term "multistage" refers to this series of impellers. As fluid passes sequentially through each impeller and its associated diffuser, the pressure is progressively increased. This design makes them exceptionally suited for applications demanding high head (pressure) that a single impeller cannot generate efficiently. The horizontal arrangement often simplifies maintenance and is ideal for installations with limited vertical space but ample floor area.

The Core Working Principle: Pressure Amplification in Stages

The operation of a horizontal multistage pump is a brilliant application of centrifugal force, repeated across several stages to achieve a high final pressure. While the overall flow rate remains relatively constant, each stage adds to the pressure. The process can be broken down into a few key steps:

- Initial Intake: Fluid enters the pump through the end suction inlet at a low initial pressure. It flows directly into the "eye" (center) of the first impeller.

- First Stage Energizing: As the motor rotates the shaft, the first impeller spins at high speed. The impeller's vanes catch the fluid and, through centrifugal force, accelerate it radially outward at high velocity.

- Energy Conversion in the Diffuser: After leaving the impeller, the high-velocity fluid enters a stationary diffuser. The diffuser is a casing with carefully designed channels that slow the fluid down. According to Bernoulli's principle, this conversion of kinetic energy (velocity) into potential energy results in a significant increase in pressure.

- Sequential Boosting: The now-pressurized fluid is expertly guided from the diffuser into the eye of the next impeller. This second stage repeats the process, taking the already pressurized fluid and boosting it to an even higher pressure.

- Final Discharge: This sequence continues through all subsequent stages. After passing through the final impeller and diffuser, the fluid, now at its maximum pressure, is directed to the discharge outlet and into the system.

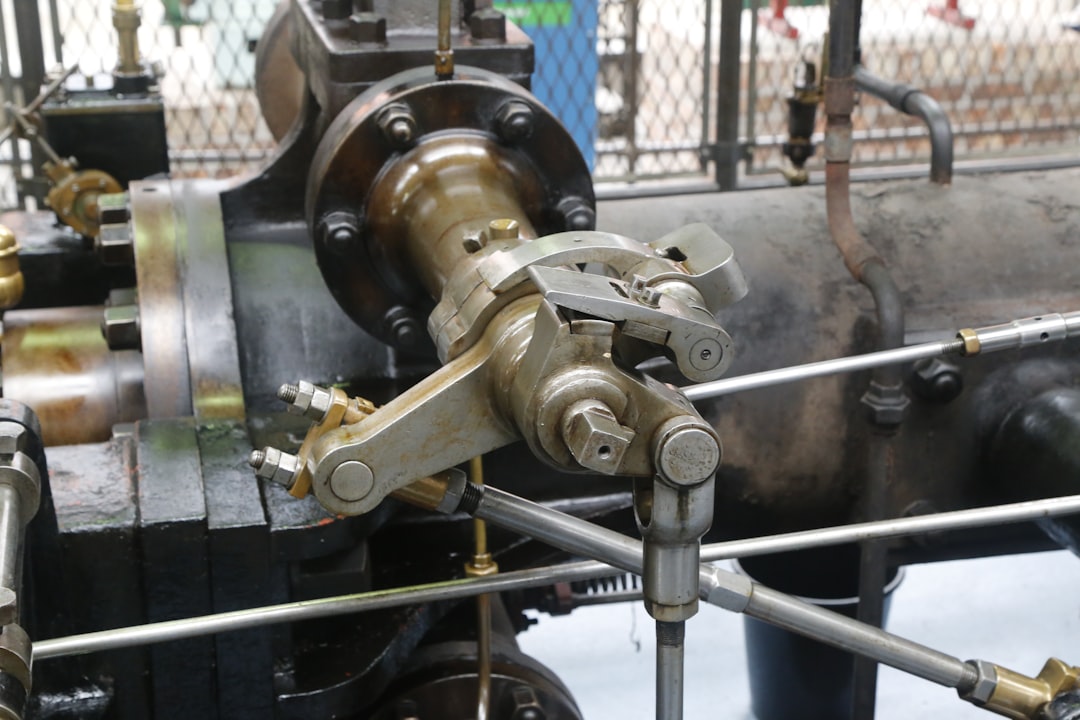

Deconstructing the Pump: Key Components and Their Functions

Understanding the components is crucial to appreciating how these pumps achieve their performance. Each part is meticulously designed to contribute to efficiency and durability.

| Component | Function |

|---|---|

| Impellers | Rotating wheels with vanes that impart velocity to the fluid. Multiple impellers in series are the heart of the multistage design. |

| Diffusers | Stationary elements surrounding each impeller that convert the fluid's velocity into pressure. They also guide the flow to the next stage. |

| Shaft | A central rotating rod that mounts all the impellers and is driven by the motor. Its stability is critical for smooth operation. |

| Casing | The outer housing that encloses all the stages and contains the fluid under pressure. It includes the suction and discharge nozzles. |

| Bearings | Support the shaft at both ends, allowing it to rotate freely with minimal friction and withstand the forces generated during operation. |

| Mechanical Seals | Positioned where the shaft exits the casing, these seals prevent fluid leakage, which is vital in high-pressure applications. |

Why Choose a Horizontal Multistage Pump? Key Advantages

These pumps are not universally applicable, but in their niche, their benefits are undeniable. They are selected for their combination of high pressure, efficiency, and reliability in specific scenarios. Key advantages include:

- High-Pressure Capability: Their primary benefit is the ability to generate very high pressures, essential for boiler feeds, reverse osmosis, and long-distance water transfer.

- Energy Efficiency: By breaking down the pressure generation into smaller, optimized stages, multistage pumps can operate closer to their Best Efficiency Point (BEP) across a range of conditions, saving energy.

- Ease of Maintenance: Compared to their vertical counterparts, horizontal pumps offer easier access to bearings and seals for inspection and repair without needing to dismantle the entire motor assembly.

- Stability and Lower Vibration: The horizontal orientation, mounted on a solid baseplate, provides excellent stability, which often results in lower vibration and quieter operation.

Horizontal vs. Vertical Multistage Pumps: Which to Choose?

While both serve the same fundamental purpose, the choice between a horizontal and vertical configuration depends heavily on the installation specifics. Horizontal pumps require a larger footprint but are easier to service. Vertical pumps, in contrast, are ideal for applications with limited floor space, such as in high-rise buildings, though maintenance can be more complex.

Common Applications Across Industries

The versatility and power of horizontal multistage pumps make them a cornerstone in various sectors:

Industrial and Manufacturing

From feeding high-pressure boilers in power plants to providing high-pressure water for industrial cleaning and processing, these pumps are a workhorse.

Water Supply and Treatment

They are critical for municipal water distribution networks, boosting pressure to serve tall buildings and remote areas. In water treatment, they provide the necessary force for reverse osmosis (RO) and desalination systems.

Agriculture and Irrigation

For large-scale agricultural operations, these pumps can efficiently move water over long distances and hilly terrain to supply irrigation systems.

Mining Operations

In the demanding environment of mining, they are used for dewatering deep mine shafts, where water must be lifted from significant depths.

Snowmaking and Firefighting

Creating artificial snow on ski slopes and powering high-pressure firefighting systems are other common applications where high head is a must.

Installation and Maintenance Considerations

Proper installation is key to the longevity and performance of a horizontal multistage pump. Critical steps include ensuring a rigid, level foundation and precise alignment between the pump and motor shafts to prevent premature bearing wear and vibration. Regular maintenance should involve monitoring bearing temperature and lubrication, inspecting seals for any leakage, and periodically checking the pump’s performance against its original curve to detect wear.

Enhancing Performance with Hydraulic Modules

Modern horizontal multistage pumps feature hydraulic modules that allow for greater customization. Impellers can often be trimmed to precisely match the required duty point, maximizing efficiency. Some designs even allow for inter-stage bleed-offs, enabling the pump to supply fluid at different pressures from a single unit.

Quieter Functionality as a Standard

Due to their balanced design and stable mounting, horizontal multistage pumps generally operate with less noise and vibration than other high-pressure pump types. This makes them a more suitable choice for installations near residential areas or in noise-sensitive industrial environments.

The Future of High-Pressure Pumping

As industries continue to demand greater efficiency and reliability, the design of horizontal multistage pumps evolves. Innovations in materials science, bearing technology, and smart monitoring systems are further enhancing their durability and reducing lifetime operating costs. These powerful machines are set to remain a fundamental component of high-pressure fluid systems for years to come, embodying a perfect balance of power, precision, and performance.